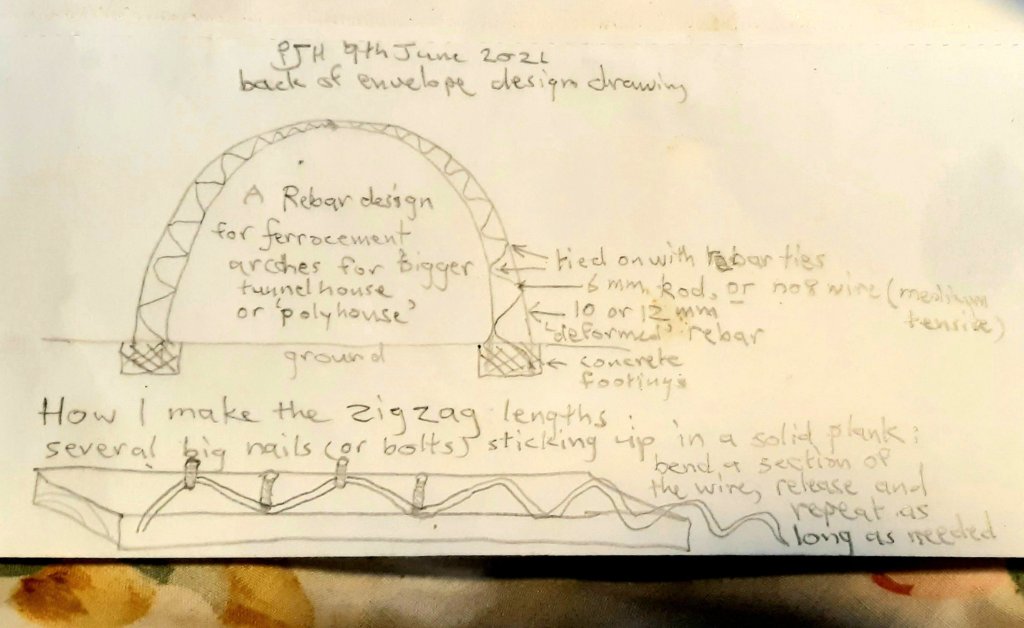

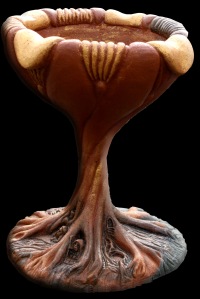

I did this (based on the cafe eutopia fountain we did 12 or so years ago now, still the centrpiece of the courtyard) the week we returned to Gisborne for the birth of our first grandchild (Bruno – he’s doing well, looking forward to seeing him play around the carved raised beds we made… As you can see, a few more sleeps before that can happen!).

Anna wasn’t sure about doing water in it so I just made it as a birdbath for now. The ‘finished’ photo isn’t quite – it rained overnight and the paint wasn’t quite dry enough to do the ‘shadowing’ effect by painting on black acrylic paint then wiping it off – you can see the parts where I did manage to do it before I had to catch the plane back home!

the whole thing took about 2-3 full days I guess. Carved mainly with the tungsten paint scraper I recommend in the book Fantastic Ferrocement. http://www.smashwords.com/books/view/152684

I did make a smaller tungsten chisel for the fine details that were in deep inside the ‘tree roots’ where the scaper couldnt reach. I will post on that later – when I’ve perfected it!

Five 6mm rods were the upright reinforcing, with roughly 2mm soft wire wrapped around it to make a finer armature for the two layers of chickenwire (more than two counting inevitable overlap on the curves). Instructions in Fantastic Ferrocement stand – some minor developments, such as using straight rebar tie wires instead of bag ties for tying the rebars together.

Note the whitish first coat – Resene Limelock to seal in the lime for painting before the plaster is cured. The twist going up the ‘trunk’ is all added – carved into the second thick coat of plaster. Also the ‘roots’ all carved from the extra thick plaster around the base.

I noticed again doing this how good it is to use plenty of plasticiser and mix in the concrete mixer longer than usual for the second coat, until the mix is aerated and wonderfully light and creamy to spread on. Also of course used plenty of fibre. These two things made it possible to get around a one inch to two or three inch (25-75mm) layer near the base – in one coat.

A deep birdbath/fountain like this can be made safe/shallow for little children by putting gravel in it, I think.

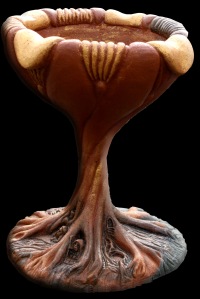

It went so well, while my other stuff (more conceptual things like the Qor game, and my philosophical writing) has been falling on indifferent ears, that I’ve decided to take several people’s advice and do art for a change, sculpt and perhaps paint again, etc. And maybe make enough to keep bank, wife and kids happier…:) I did a little oak carving recently, in that spirit:

Moonwit Dreams, from my fantasy epic the Apples of Aeden. I made a silicone mould for it too, and have tried some casting in plaster of Paris, oil-finishing the casts by dipping in hot linseed oil, then finishing by ‘shadowing’ as in the original above with dark acrylic.

For any ferro or carved work you want to commission, email me peter@eutopia.co.nz.

-36.157109

174.441107